Bhabha Research Atomic Centre has developed a process for preparation of Thin Film Composite (TFC) Charged Nano-filtration (NF) Membranes containing surface negative charge in the form of fixed sulfonic acid (-SO3-H+) groups.

This has tremendous potentials for applications in aqueous stream separations such as in production of potable water from partially brackish hard water, removal of heavy metal contaminants, removal of microbial (bacteria/virus) contaminations, pre-treatment of saline water for desalination processes like RO and MSF, and a host of other areas like pharmaceuticals and bio technological industries, downstream processing, food and beverage industries, dairy industry, waste water treatment.

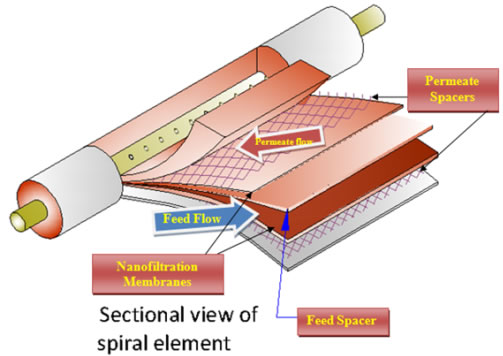

The membranes work under the principle similar to reverse osmosis where pressure is applied on the feed side of the membrane resulting in the desired operation. However, the performance of these charged nano-filtration membranes can be tailored by incorporation of appropriate charge in them which results in the unique property of the membranes enabling them for fractional separation of various solutes. The membranes operate under lower pressure than the reverse osmosis but still produce higher flux. Generally 10 bar applied pressure is suitable for these operations with a feed concentration of about 2000 ppm.

For further details contact: Bhabha Atomic Research Centre Telephone: +91-22-25505050 / 25592000, Email: webmaster@barc.gov.in

ALSO READ:

BARC technology for Composite Polyamide Reverse Osmosis membrane for Brackish Water Desalination

Polymeric, electrochromic smart window that can store energy

Chlorine Dioxide releasing polymer for water disinfection (CLEAN)

Multi Effect Distillation with Thermo Vapour Compression Desalination Technology