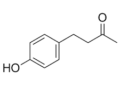

The Central Leather Research Institute of CSIR (Council of scientific and Industrial Research) has developed a technology to create a re-tanning agent from lignin. Effluent from the paper and pulp industry, predominantly contains large amounts of polyphenols like lignin and fragmented lignin. The leather industry consumed a large amount of synthetic phenol-formaldehyde resin as a re-tanning agent to improve the homogeneity and organoleptic properties of leather and the presence of free formaldehyde in leather is a major concern because of its carcinogenicity.

The development phenolic re-tanning agent devoid of formaldehyde is critical for effective waste management and environmental welfare. Waste liquor collected from the leather and tanning industry has been chemically modified and used as a re-tanning agent in leather manufacturing.

Some of the highlight features of this technology include; utilization of the paper and pulp industry as a re-tanning agent, product is free from formaldehyde, imparts excellent soft touch and wet feel to the leather, smooth and fine grain and compatible with all kind of syntans, vegetable tannins & fat liquors.

This technology is ready for commercialization.

For further details contact: director@clri.res.in, +91 44 2491 0897 / 2443 7131

ALSO READ:

ISRO develops high silica cloth

BARC has technology for producing flame-retardant cotton cloth

UV shielding bio-derived furanic polymers.

Leather like materials made out of plant waste

DRDO technology for hydrophilic, breathable polyurethane resin

A Rapid Composting Technology for decomposition of dry leaves, kitchen waste and temple waste

From Tea & banana waste non-toxic activated carbon

Process for the preparation of finely divided precipitated silica for different applications