If you can pack sugarcane juice in bottles or tetra packs, you have yourself a great business opportunity. Today, however, sugarcane juice can be consumed only as soon as the juice is extracted from the cane, as its quality deteriorates rapidly with passage of time, due to microbial activity. But a researcher at IIT Kharagpur has come up with a technology to give sugarcane juice a shelf life.

Sugarcane juice is a refreshing drink with an enriched nutritional profile. The juice accommodates health components such as, phytonutrients, antioxidants, and vitamins (like Vitamins C&B) which offer quick relief from heatstroke, dehydration, constipation, jaundice, etc. by supplying instant energy. Owing to the absence of simple sugars and low glycemic index (30-40), its average intake by diabetic persons is also acceptable. However, the color and flavor unique to the juice get deteriorated immediately after its extraction due to biological processes of browning and microbial fermentation. Its short shelf life limits its long-term storage and marketing. Thermal treatments used to enhance the shelf life of sugarcane juice destroy its pleasant taste and aroma. Non-thermal methods hold promise in this regard.

Research scholar Chirasmita Panigrahi from the Dept. of Agricultural & Food Engineering, as part of her PhD research, has been pursuing a novel study on ozone assisted cold sterilization technology towards the shelf stabilization of sugarcane juice without heat or chemical.

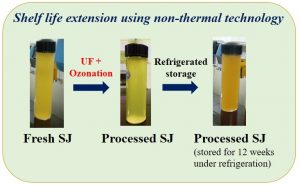

The process technology involves ultra-filtering and ozonization of the freshly extracted microfiltered juice followed by packaging under an aseptic environment. The combined membrane filtration and ozone treatment technology resulted in 7 log reduction in bacteria, 5 log reduction in yeasts & moulds and 85% inactivation of enzyme polyphenol oxidase.

The process technology involves ultra-filtering and ozonation of the freshly extracted microfiltered juice followed by packaging under an aseptic environment. The combined membrane filtration and ozone treatment technology resulted in 7 log reduction in bacteria, 5 log reduction in yeasts & moulds and 85% inactivation of enzyme polyphenol oxidase. This will minimize the juice fermentation and brown to a greater extent during storage. The combined technology treated juice could be successfully stored up to 12 weeks under refrigeration without any appreciable change in its bioactive and essential nutrients. The treated juice well retained its sensory characteristics especially the color and flavor during storage.

For more details, contact: For more information please contact Prof. H N Mishra at hnm@agfe.iitkgp.ac.in (Professor Mishra is Chirasmita Panigrahi’s guide).