The Central Salt and Marine Chemical Research Institute (CSMCRI) has developed a technology for the process of recovering common salt and marine chemicals of high purity in integrated manner. The process is amenable to a wide range of brine compositions that are low in sulphate content and yield impure salt when the conventional process of solar salt production is followed. It is for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner.

The process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern which produces carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

The technology has been validated in CSIR-CSMCRI ESF/ pilot plant. The process / technology is ready for technology transfer and can be implemented on commercial scale. The product has high demand in industrial sector. The technology is at a TRL of 7.

For further details contact:

Director CSMCRI, Dr Kannan Srinivasan, Ph. No.+091-278-2569496 E-Mail: director@csmcri.res.in

ALSO READ:

CSMCRI develops technology for producing pure salt for industrial use

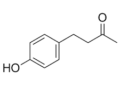

A cost-effective and greener process for 3-methyl-5-phenylpentanal (mefrosol)

Production of high purity heavy basic magnesium carbonate from bittern

Process for the preparation of finely divided precipitated silica for different applications

IICT has a ‘bio-electro-chemical’ route for treating complex wastewater

Biogas generation from organic wastes

Process for the preparation of finely divided precipitated silica for different applications