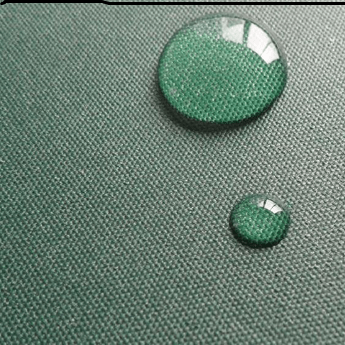

The Defense Research and Development Organization (DRDO) is making available technology for hydrophilic, breathable polyurethane coating resin for transfer to industry. The organization has developed indigenous waterproof breathable polyurethane resin formulation, which can be used for coating fabrics. The developed PU film exhibits an excellent combination of waterproofness (~100 mbar), tensile strength (~ 4Mpa) and breathability (~ 1400 g/m2 /24h). The coated fabric prepared using the developed breathable hydrophilic PU resin exhibits waterproofness > 500 mbar and breathability > 1000 g/m2 /24h. PU resin coated directly on base fabrics has a lot of potential in sportwear, rainwear, specialized military clothing etc.

Hydrophilic breathable polyurethane coating resin Breathability is a property of materials and composites, which permits the escape of moisture and the heat associated with that moisture from the interior of the garment to the outside environment.

In general, fabrics exhibiting a combination of waterproofness, wind proofness, and water vapor permeability are referred to as breathable fabrics. These fabrics constitute one of the major components of individual protective clothing used in fire protective clothing, High altitude conditions, sportswear etc. Present generation breathable fabrics use water vapor permeable polymeric membranes for this purpose.

The typical thickness of these membranes is ~10-30 micron, which is coated or laminated on a woven/ non-woven fabric to arrive at a fabric of requisite mechanical strength. These membranes can generally be categorized into two types based on the underlying principle behind their breathability: microporosity and hydrophilicity. In microporous membranes, the pores are designed to be too small to permit liquid water penetration; however, they are large enough to allow free passage of vapor in water.

On the other hand, breathable non-porous polymeric films are hydrophilic films that contain chemical functionalities capable of absorbing, diffusing, and desorbing the water in the form of vapor. These films are not porous and are hence water impermeable. In this latter scenario, the breathability is attributed to the molecular absorption-diffusion-desorption mechanism, which in turn is driven by the temperature and humidity gradient. Most commercial hydrophilic polymeric membranes or coatings are based on polyethylene oxide copolymers with ester, amide, or urethanes.

For further details, contact:

D.C.Joshi

Chief (Business Development)

National Research Development Corporation

20-22, Zamroodhpur Community Centre, Kailash Colony Extn. New Delhi – 110048 INDIA

Mobile : +91-9910496565 Email : dcjoshi@nrdc.in

Also read:

Small molecule investors seek industry collaboration

Solar icebox for preservinf fish

Novel composite materials developed for high-temperature batteries and supercapacitors

Technology for making useful products from dried mango leaves