Professor Satya Seshadri of IIT Madras has invented a device to avoid wasting steam in industries. The device makes use of the steam to produce electricity. Though similar devices exist in the market, this one is a technological improvement in many terms.

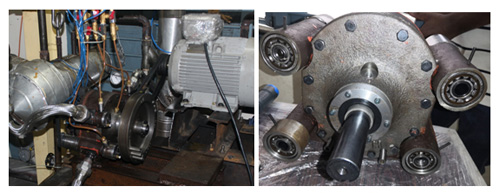

The device is called ‘expander’. How it works is as follows:

A lot of steam is generated in industries such as textiles, dairy, rice mills, as they need steam for their processes. The steam is produced in boilers at high pressures (10-25 bars) but stepped down by a throttle valve to deliver low-pressure steam (2-8 bars) at the points of use. Because of this, a lot of potential energy in the high-pressure steam is lost.

The expander designed by Professor Seshadri replaces the throttle, but performs the same function of reducing the pressure. Inside the expander the steam pushes a rotor connected to a generator, producing electricity. Seshadri tells www.rndnews.com that steam from a 1 tph boiler can give 20-35 kW of power. The cost of the system can be paid back in 18 months because of the power generated.

By adjusting the port opening duration dynamically by sensing the process load, the technology developed in EnERG lab completely avoids throttling ahead of admission for variable load operation and hence can maintain the efficiency of the expander for a wider range of turndown conditions.

The expander is an improvement over the conventional ‘energy conservation turbines’ because it can handle large variations in steam pressure and is also not affected by water droplets in the steam. Seshadri believes that 15 GW of capacity can be created in process industries with the expander.

Those interested in accessing this technology may get in touch with Professor Seshadri at satya.s@aspirationenergy.com