Defence Foor Research Laboratory (DFRL) – DRDO has developed Biodegradable Packaging Materials technology.

Excessive usage of plastics accompanied by its relatively low cost and easy availability started an era popularly known as the age of “throw away living”, where plastics are indiscriminately thrown after its single use. This has resulted in accumulation of plastic waste everywhere, which is disturbing and damaging the earth’s ecosystem. The Government of India introduced Plastic Waste Management Rules, 2016, prohibiting identified single use plastic items. Recently the Ministry of Environment, Forest, and Climate Change (MoEFCC) also released guidelines to phase out single use plastics vide the Plastic Waste Management (Amendment) Rules, 2022. As an alternate to non-degradable single use plastics, Defence Food Research Laboratory (DFRL), Mysore has developed a technology to make biodegradable packaging materials (Carry Bags), which decomposes in a specific environment such as water, soil, compost etc. under a short period of time.

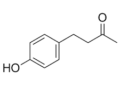

This technology is mainly focused on the utilization of biodegradable and compostable polymers such as Polybutylene Adipate co- Terephthalate (PBAT), Poly Lactic Acid (PLA), starch etc. for the production of flexible films for applications such as carry bags, pouches, bags etc. A suitable formulation was developed which can be blown into films using extrusion film blowing technique. The physic mechanical properties of the film were carried out using a tensile tester as per to ASTM D 882 and found to have sufficient strength for using in carry bag applications. These films were tested for their biodegradability and found to meet the BIS standard for compostable plastics. A soil burial test was conducted, where thee samples were found to gradually disintegrate and the biodegraded within the stipulated time period. During the process, erosion holes were first observed in the sample followed by breaking down into residual fragments. Later the film completely disappeared, indicating complete biodegradation of the film. Weight loss percentage was also recorded during the test period.

The technology is amenable for bulk production with varied thickness as per the end user requirement. Any existing carry bag manufacturer can use this technology to manufacture compostable and environmentally friendly films and carry bags. Considering the widespread usage of single use plastics in various fields, biodegradable and compostable plastics are having the potential to replace existing non degradable plastics. There is a growing demand for biodegradable plastics, which degrade in the environment, to establish a more sustainable society and to solve our environmental and waste management problems.

For further details contact: Director, Defence Food Research Laboratory (DFRL), Email: director.dfrl.gov.in, Phone: 0821-2579003, 2579004, 2473783

ALSO READ:

Biodegradable cutleries, cups, glass and plates from agro wastes

Process for development of weather resistant coir geotextile

Bio-degradable Lignocellulosic Fibre-based Mulching Mats and Sheets for Modern Farming

IIT Jodhpur technology for recovery wastewater from textile units