The Bhabha Atomic Research Center (BARC) is offering technology for producing biodegradable packaging films prepared by extrusion process using gaur gum and polyvinyl alcohol. This technology is priced at Rs 4 lakhs.

BARC says that an alternative for plastics are biopolymers, which are usually made from polysaccharides and lipids. The most widely studied polysaccharides biodegradable films are: starch, chitosan, carrageenan, and galactomannans. However, there are several limitations in the use of biopolymers as packaging materials such as their relatively poor mechanical strength and lower barrier to water and gases like CO2 and O2 as compared to their non-biodegradable counterparts. This has resulted in a greater focus on improving the properties of these polymers to match the commercially available packaging material. Various methods including addition of plasticizer, chemical modifications, gamma radiation and use of different additives for improving properties of natural biopolymer based films are reported in literature. However, generally in literature preparation of biodegradable films are detailed by solvent casting technique which is extremely difficult to scale up industrially.

Therefore, there is a need for technology to prepare biodegradable films employing extrusion processing which can be easily scale up industrially. Currently available commercial thermoplastic polymers amenable for extrusion processing such as poly lactic acid (PLA), poly butylene adipate-co-terephthalate) (PBAT) and Poly Hydroxy Alkanoates (PHA) have disadvantage for very high cost.

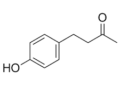

Preparation of biodegradable films using extrusion processing having comparable cost to that to petroleum-based polymers is required. Guar gum is a biopolymer and is widely available in India. In present technology, suitable methodology is described to prepare films from guar gum employing extrusion technology.

BARC’s method for preparing biodegradable films using extrusion process. Process involves three steps: 1) Preparation of plasticized guar gum 2) Making compound of plasticized guar gum and poly vinyl alcohol in twin screw extruder 3) Making films by blown film extrusion

- Preparation of plasticized guar gum: Plasticized guar gum is prepared by mixing guar gum with suitable plasticizers and additives and subjecting the mixture to desired time temperature conditions.

- Making compound of plasticized guar gum and PVA: Plasticized guar gum obtained above is mixed with desired grade of PVA and mixture is subjected to twin screw extrusion in presence of compatibilizer. Strands obtained are cut in form of pellets.

- Making of films by blown film extrusion: Pellets obtained above are then subjected to blown film extrusion in a single screw extruder and films are formed.

RAW MATERIALS

- Guar gum

- Poly vinyl alcohol

- Plasticizers and compatibilizers

- All the raw materials required are available in the local market.

EQUIPMENTS

- Twin screw extruder

- Single screw extruder equipped with blown film attachment

- Hot air oven

- Industrial grade powder mixers

SPACE

- Factory shade of 2000 sq. ft. area (50 ft. x 40 ft) with DM water facilities

POWER

- Three phase power connection

MANPOWER

- Minimum two laboratory technician are required for production of one ton of films. Actual manpower would depend on production capacity

This technology results in good alternative for plastics for packaging material. The advantages are:

- Develop biodegradable films present an attractive alternative to petroleum based polymers like LLDPE, LDPE, HDPE, PP etc.

- Concentrations of additives can be easily modified to tailor film properties.

- Can be prepared using industrially available extrusion processing

The best applications are in general purpose packaging material such as carry bags and food packaging.

For further details, contact:

Head, Technology Transfer and Collaboration Division

Bhabha Atomic Research Centre,

Trombay, Mumbai 400 085.

Fax :+91-22- 25505151

technology@barc.gov.in

ALSO READ:

IISc Bengaluru offers technology for biodegradable plastics

Technology for making useful products from dried mango leaves

Technology to extend shelf-life of sugarcane juice

Seaweed farming is a lucrative business opportunity

Extraction of polyphenols from green tea leaves

Making yoga mats from water hyacinth